As Façade Contractors and interior contractors, we follow stringent quality policies before any project is designed for a new building. We recommend the following practical

considerations at an early stage.

• Structural requirements of the building (present and future)

• Public safety at all times

• Wind load Calculations during different weather conditions

• Weather resistance – the ability of the façade to withstand unfavourable weather

• Easy to maintain buildings

• Optimum and lasting colour finishes

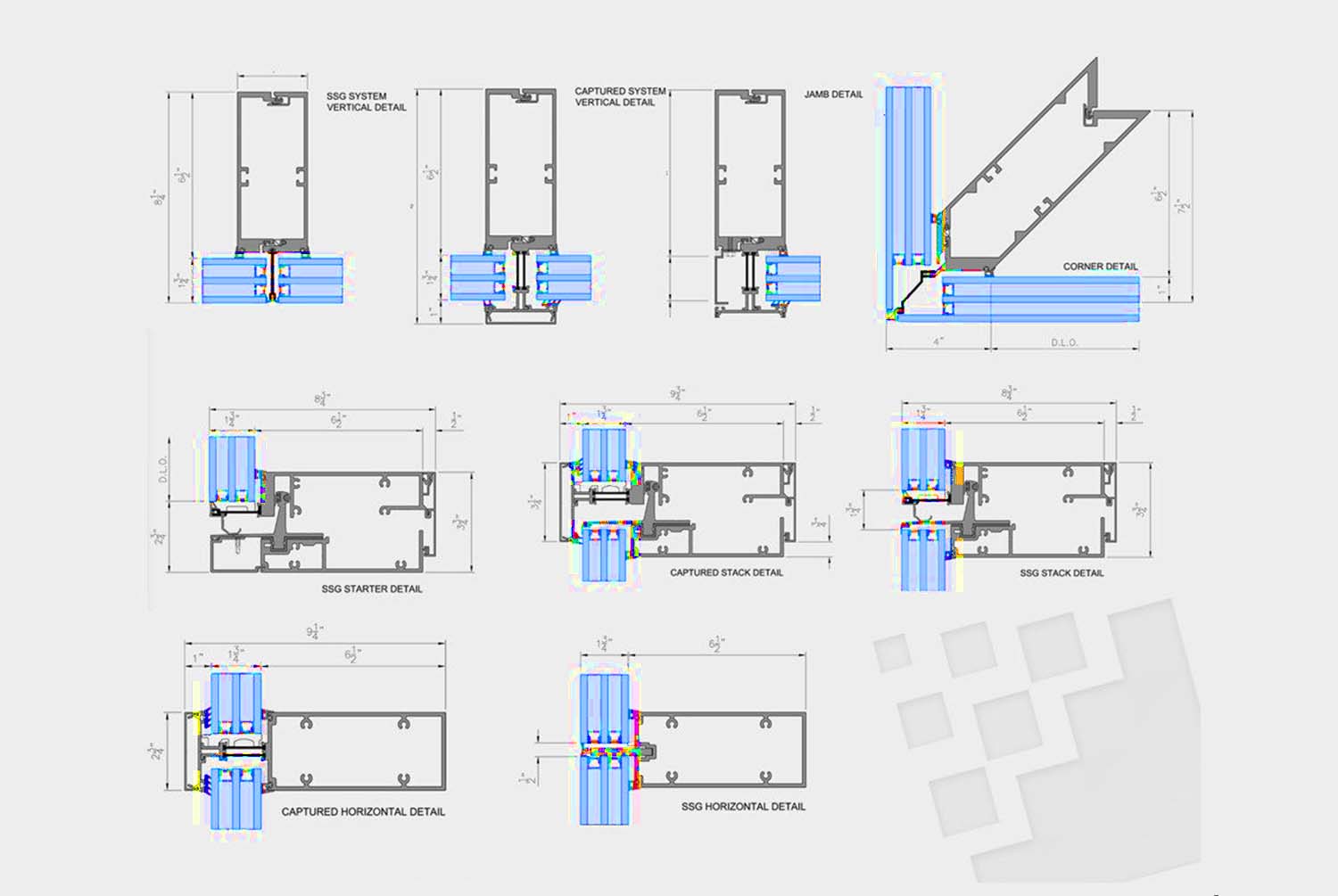

We use it in structural glazing, stick glazing and all types of doors and windows. The ideal extrusion alloy that conforms to the best and easy maintenance. We also ensure that the extrusion is clean, straight with defined lines and free from defects or distorts that can impact its appearance, strength or durability. It’s also suitable for wall thickness due to its rigidity and strength, that’s tensile for bending and bearing stress. It is also capable of delivering local and lateral stability.

We fix the structural glazing system to the main structure of your building using components of alloy steel or other appropriate materials that conform to the statutory requirements. Galvanized steel brackets are usually used as anchorage systems and are selected per engineering calculations. They can withstand 200 kg/sq. m x 1.5 times for optimum safety. Millions are mounted to the brackets as per the desired thickness and size. We use fastening and transoms of stainless-steel bolts and nuts with spring washers.

We only use approved glass that can withstand the wind load as specified by your architect. The glass samples are submitted for approval before fixing. We’re the only dealers of Saint-Gobain in the entire area and offer best-in-class solutions for your requirements.

We document the entire process in writing for review and approval from engineers to ensure design integrity and performance. It includes the details, schedules and explanatory sketches cross-referenced to the drawings.

Trust our team to also provide the fabrication and installation in accordance with the contract documents.

Our quality process includes the following:

• Visual inspection and field tests of materials

• Tolerances, joinery, and sleeves of fabrication

• Approved finish matches for the exposed surfaces

• Assembly of the welds, sealants, glazing, bite, gaskets, and fasteners

• Protection and handling care while shipping

• Anchorage of lines, grades and building tolerances

• Installation processes with all quality materials

• Sealing support as per the manufacturer’s recommendations

• Storage that aligns with the demands of the building and manufacturer

• Protection and cleaning as per the material